Manufacturing Surveillance of Unbonded Flexible pipes to Comply with API 17J

We are specialists in the manufacturing of Unbonded and Bonded Flexible pipes. Our specialist are familiar with the manufacturing processes, materials and procedures used in the construction of Risers and Flowlines. We are also conversant with the Flexible qualification process and testing required for Flexibles

Qualification Testing Reviews to API 17B and Proprietary Qualification Requirements

Unbonded and and Bonded Flexibles’ are a custom designed product requiring a qualification process for a particular duty. Our specialists are conversant with the requirements of the qualification process to satisfy API 17J and 17B. The qualification process covers full scale testing of static, dynamic riser pipes and thermal performance testing (TEC).

Materials Qualification and Manufacturing Procedure Review to Comply with API Standards for Unbonded Flexible Pipes

Our specialists are conversant in the qualification requirements for materials used in the construction of Flexible pipes and umbilicals. From exotic materials used in the carcass layer through to the outer sheath polymer layers and pipe termination components.

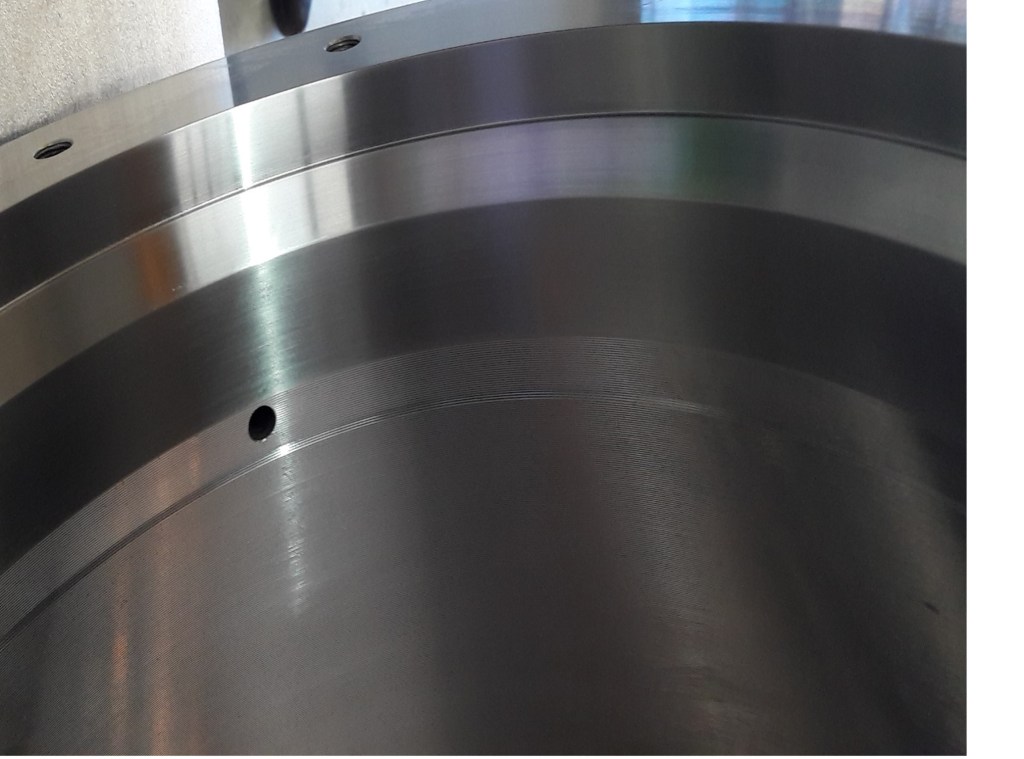

Production Quality Surveillance

Our team offers a unrivalled onsite inspection service that monitors the production process through its manufacturing life cycle with the capability to identify production issues with the potential to impact on the final product quality.

Factory Acceptance Tests, Equipment Sign-off, Inspection Release Notes

Our team can attend for final product factory acceptance and testing. They can also review final project documentation prior to production of Inspection release notes. They are conversant with a wide range of final testing from load testing to wet hydrostatic and air testing at extreme pressures. We also have experience of Forensic examination and failure mode investigation and problem identification.

Manufacturing Scheduling and Expediting

We can offer a service in manufacturing scheduling and assist in expediting of products and components.

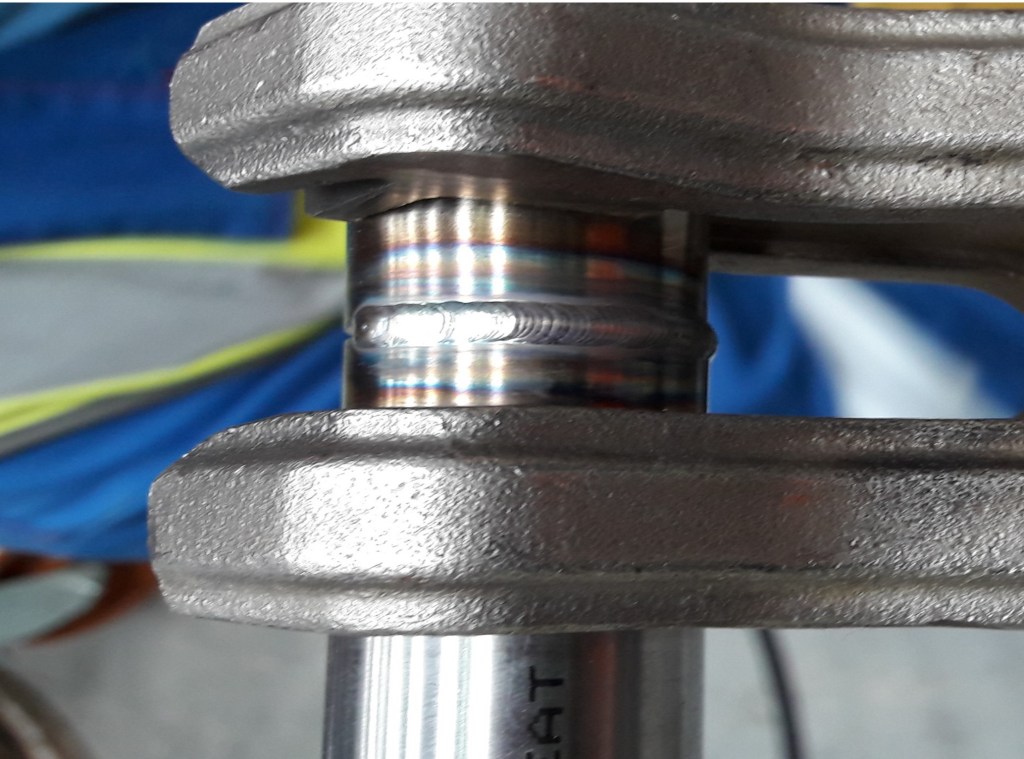

Welding Control

We can offer a service in monitoring welding according to ASME VIII, and EN standards.

Inspection Test Plan (ITP) Reviews. Identification of Critical Manufacturing Activities.

Our specialist team can assist in reviewing inspection test plans for Flexible pipes and associated ancillary equipment. We can also offer a general service for smaller companies with limited experience of inspection test plans and quality systems required to comply with the requirements of the Oil and Gas industry.

Vendor Qualification and Audit Reviews

Safety critical equipment requires that the manufacturer has the required process that are tightly controlled and can be operated with consistent and proved reliability. throughout the manufacturing cycle. Full quality documentation and the reporting of potential defects relies on a controlled quality control process that captures relevant product information that confirms the quality requirements. Our specialists can carry out audits in a consistent manner.

Pre-Production Meetings and Schedule Review.

The FlexInspex team can provide independent assessment of the overall production schedule and identify potential issues prior to commencement of production.

Test House Audits and Final Load Testing

Our specialists can carry out audits to confirm the capability of the test house and monitor the final testing in accordance with the project or customer requirements.

Final Inspection and Packaging

We can assist in the final packaging and product checks required before final despatch and shipping. We can also assist with loadouts of Flexible either carousel runs or reels.

Select the button below to contact FlexInspex for further information.